Radio Frequency Identification (RFID) is an automatic identification technology that has to come into broad acceptance across multiple industries, including aviation. It brings benefits beyond bar code technology. Where bar codes need light to transmit and receive data, RFID uses radio waves to transfer data to/from RFID tag.

The specific function of these radio waves is that they go through, around, in, under, and behind objects to reach a tag. The technology can also see hundreds of tags per second, so it appears to gather data instantaneously. That enables an entirely new set of opportunities for the airline. Examples are, in quickly determining if every airplane seat has its life vest hidden underneath, or if security has been breached on any life vest boxes. Other examples include reading if any oxygen generator that is still closed up in the Passenger Service Unit will expire in the next month, or if all the medical kits are still sealed.

The handheld portable RFID readers usually come with the capability to read bar codes as well as RFID tags. This is extremely useful to use both technologies in conjunction with each other.

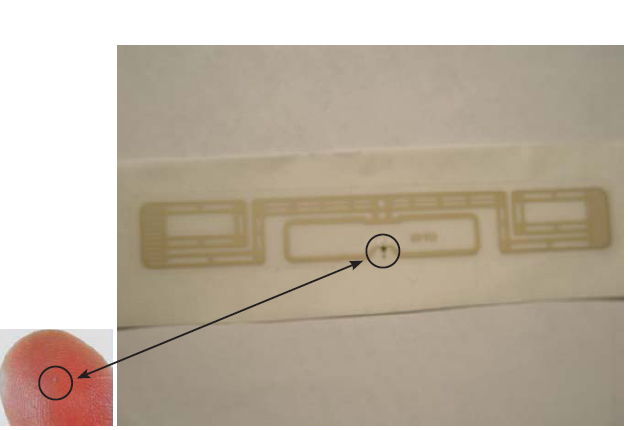

Inside the tag, the chip converts the radio wave into DC power, converts a radio-frequency (RF) signal to useful information, stores data in four separate memory banks, handles sophisticated communications with the reader, checks error codes on every communication, decodes passwords, and other specialized functions.

A complete RFID system requires several components: an RFID tag (chip + tag antenna), an antenna to send out and listen for radio signals, a reader connected to the antenna to decode the digital signals, and a computer system to control the process and store/use the data from the tag.

This section shows a list of some of the RFID opportunities in the airline operational area:

The Maintenance & Engineering (M&E) functions rely on knowing exactly which item was installed at which location on which aircraft by exact serial number – not just a part number. RFID can quickly, easily, and correctly identify that serial number from a tagged part with no human mistakes to invalidate the data. Such data is currently stored in the airline’s official System of Record, but with the advent of industry standards and high memory, RFID tags this data, which can also be stored on the part as a portable traceability record.